Innovations in Grouting

Techniques: A Game-Changer

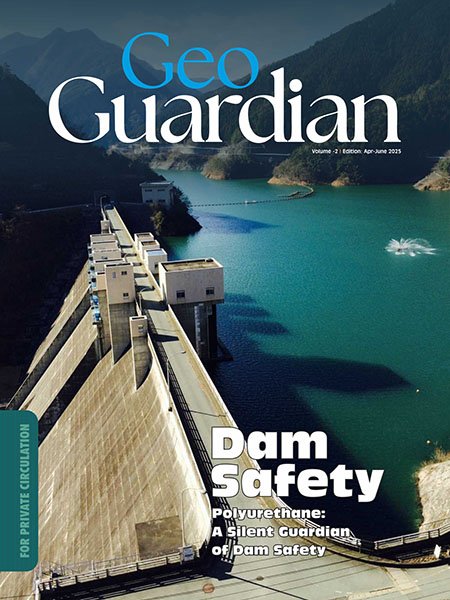

Grouting—a core tool for improving ground stability—is undergoing a technological renaissance. Engineers

now have a broader palette of grouting options to address specific site challenges with greater precision

and speed.

Chemical grouts, such as polyurethane and sodium silicate, are enabling soil stabilization in difficult

conditions where traditional cementitious grouts fall short. Jet grouting, capable of creating high-strength

soil-cement columns deep below the surface, is providing new opportunities for foundation enhancement and

seepage control.

Automation is streamlining the grouting process. Computer-controlled grouting rigs reduce variability in

pressure, flow, and mix ratios, ensuring consistent results and improving project efficiency. Sensors

embedded in injection points monitor real-time grout spread, giving engineers greater control over outcomes

while reducing material waste.

These advancements are particularly vital for projects in urban environments, where tight schedules, space

constraints, and sensitive surroundings demand reliable, high-precision solutions. Grouting is no longer

just a reinforcement tool—it’s a strategic enabler for safer, more resilient infrastructure.